2-Axis cable-activated leak free pipe joint in Solidworks

- Status: Closed

- Prize: $100

- Entries Received: 1

- Winner: VasilVD

Contest Brief

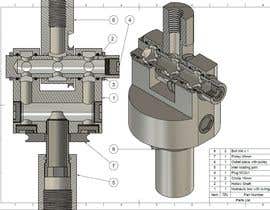

We need a flexible 2-axis pipe/tube joint that is actuated by cable and electric motors. I'm attaching a simplified image of the basic idea. We will judge the bids based on sketch entries. The winning bid will need to provide the final design in Solidworks. The design should be be leak free and ideally would be comprised of commercial, off the shelf parts wherever possible.

I have added a couple of photos that give examples of 2-axis joints. The joystick obviously isn't piping but it has the joint/motion that we would like to reproduce. The other joint picture isn't actuated but is gives another concept of how the motion of the joint can work.

Also, the fluid (water based) should not be contaminated by the joint material.

Recommended Skills

Employer Feedback

“@VasilVD won the contest on 7 July 2019”

![]() OpenThoughts, Japan.

OpenThoughts, Japan.

Top entries from this contest

-

VasilVD Bulgaria

Public Clarification Board

How to get started with contests

-

Post Your Contest Quick and easy

-

Get Tons of Entries From around the world

-

Award the best entry Download the files - Easy!